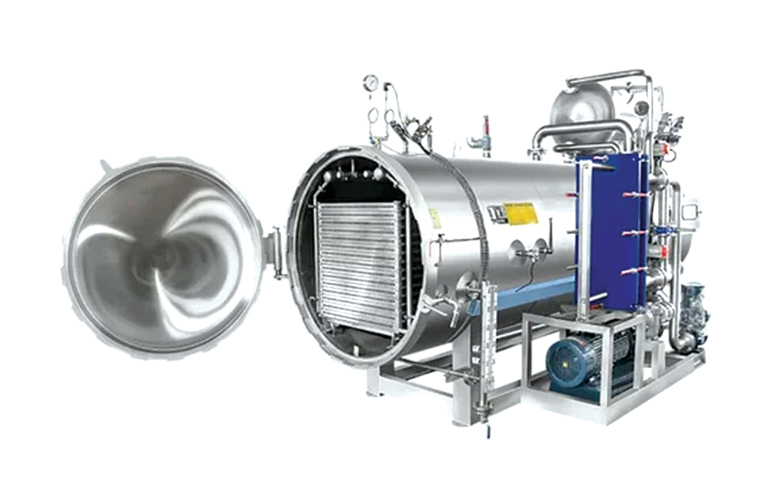

Bottle Retort

The machine likely incorporates advanced retort processing technology to ensure effective and efficient heat treatment of flavored milk bottles. DEA's machine may feature precise control systems for temperature, pressure, and processing time, allowing for customization based on different flavored milk formulations.

To guarantee product quality, the retort machine would likely ensure uniform heat distribution across all bottles, preventing hot spots and ensuring consistent pasteurization. Manufacturers might be able to tailor processing parameters according to the specific requirements of different flavored milk products.

For specific and up-to-date information on the "Flavoured Milk Bottle Retort Machine" manufactured by DEA, I recommend reaching out directly to DEA or checking their official website. This will provide the most accurate and detailed information regarding the features, capabilities, and specifications of their retort machine designed for flavored milk bottles.

- The advanced technology and customization options of DEA machinery lead to increased production efficiency.

- DEA machinery incorporates the latest technological advancements, ensuring efficiency, precision, and reliability in food processing operations.

- High-quality materials and robust manufacturing standards result in machinery that is durable, capable of withstanding continuous and intensive use in demanding production environments.

- DEA machinery is designed with hygiene in mind, featuring easy-to-clean surfaces, stainless steel construction, and compliance with industry sanitation standards to ensure food safety.

- DEA machinery is versatile and adaptable to various food processing sectors, including meat, bakery, dairy, and beverage production, providing a comprehensive solution for diverse industries.

Ready to take your food processing business to new heights? Choose DEA, the industry leader in cutting-edge food processing machinery.